“GridRaster is light years ahead of everything else we’ve seen”

– Top Defense Prime and USAF

Revolutionizing Readiness with GridRaster’s AI and XR technology

We are thrilled to share a pivotal update from GridRaster that’s setting a new benchmark in 3D AI and XR technology in Manufacturing and Sustainment.

On Nov 2, 2023, GridRaster had the privilege of conducting a comprehensive workshop and demonstration at Warner Robins Air Force Base, showcasing our cutting-edge work on 3D AI and XR solutions for the US Air Force. This event attracted over 40+ attendees from a range of DoD agencies, such as US Air Force, Army, Navy, and Marine Corps, as well as leading commercial industry partners including Lockheed Martin (Space, Sikorsky, RMS and ATL), Northrop Grumman, General Dynamics, Honeywell, Delta Airlines and others. The turnout for the event was impressive and highlighted the growing interest and compelling potential of GridRaster’s innovative work in the space.

Real-time Fast and Accurate Digital Twin Creation: Humvee Vehicle

Real-time Fast and Accurate Digital Twin Creation: Humvee Vehicle

Fast + Accurate: 3D Digital Twin Creation

In a live demonstration, this Humvee model was created using the GridRaster Digital Twin Creation Software Suite using 3D AI and real-time remote streaming. In less than 10 minutes, the digital twin model was created and imported into augmented reality, with final alignment accuracy of the model to the physical vehicle in mere millimeters.

Key Result: 3D Model creation 10x faster, and at 1/10th the cost of baselines.

Faster, Better and Scalable Paint Masking on C-130 Hercules

GridRaster showcased their advanced 3D AI-powered object detection capabilities by applying a precise overlay of a 3D paint stencil onto a C-130 aircraft using GridRaster Cloud Software and HoloLens Application. This breakthrough technology boasts an unprecedented millimeter precision that is ten times better than the current state of the art. The US Air Force can now carry out paint masking operations in an operational environment using HoloLens, resulting in a 10-100 times reduction in time and cost.

Core Innovations & Technology

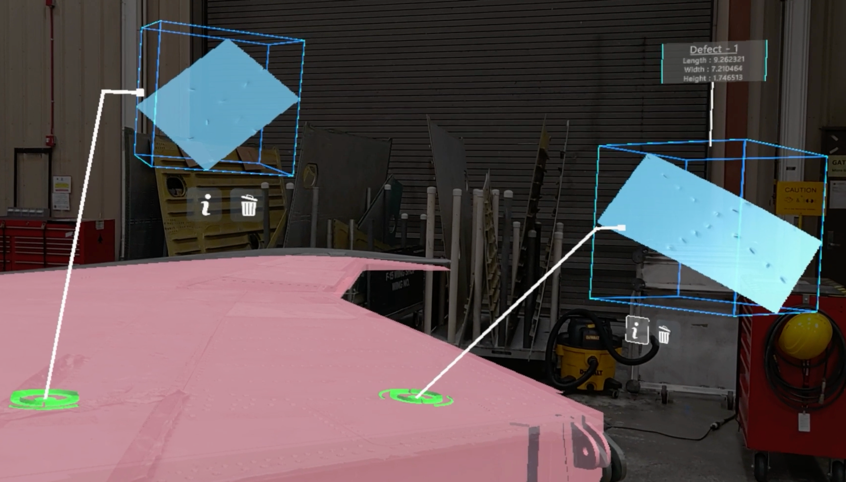

AI Powered Multi-object detection, localization and defect mapping and real-time remote XR streaming

GridRaster then showcased their AI-based technology that provides high-fidelity 3D spatial mapping, object detection, and real-time scene graph generation. With this advanced system, we demonstrated the ability to precisely locate multiple parts of an F-15 aircraft and accurately overlay exacting 3D models onto these components.

Utilizing a laser scanner in conjunction with digital twin metadata, minute imperfections within the F-15 wing were identified at an extremely high resolution. By correlating these flaws with their precise locations, a comprehensive 3D Scene Graph was constructed, and the data was subsequently reintroduced into the relevant record.

Delivering Impactful Use Cases

GridRaster’s technologies go beyond demonstration—they deliver tangible benefits::

Automation of Depot-level Maintenance, Repair and Operations to reduce rework, improve efficiency, and save cost.

Holographic Inspection of Complex Aircraft Structures for auto-detection of defects, anomalies and deviations for faster inspection, improved accuracy and better maintenance

Train users on how to operate on different assets by providing asset and state specific tasks.

Precise location and pose of the parts are sent to maintenance robots who can perform the relevant tasks on those parts.

Create asset specific digital twins to add asset specific maintenance logs, defects, and other sensor data and update the 3D digital twin in real time providing an unbroken digital thread.

A Resounding Endorsement

The workshop marked a turning point in GridRaster’s technological development, and was a huge success. The enthusiasm and support for our work culminated in a commendation from Dr. Kevin Geiss, Director, Science and Technology, in the Office of the Under Secretary of Defense for Research and Engineering at the ARM-I Annual Members Meeting, highlighting GridRaster’s efforts as “one of the three most successful and impactful on-going efforts” in Air Force Mantech.

Join the Revolution

This is an invitation to experience the cutting edge of AI and XR technology in Aerospace & Defense and larger industrial base. Partner with GridRaster, and let’s pave the way for a smarter, more efficient future in defense readiness and operational excellence.

We look forward to discussing how our solutions can meet your specific needs and elevate your operational capabilities.

Ready to get started? Contact us to learn more.